bubbamauser

-

Posts

151 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by bubbamauser

-

-

Thanks Clemson,

The first time I did this with a stone I'll be using your method next it looks good and I'm better with a file (still working on patience)

-

Forgot to log in

-

Manureman,

The 06 feeds great, I did open up the box a little on either end because someone posted a while back the box could would be too short for reloads, but when I first put the barrel in I cycled a whole magazine of remington 150 through a few times with no problems , I probably did'nt need to open it up.

Fritz,

I about 1 1/2 years ago when I started going to these sites. I posted a question over at bills site. some j*** off wrote me a nasty post about my "bubbaing historic arms" and how I am destroying history, then they posted their general reply and deleted my post. I had some lame log in so I decided Bubbamauser would be appropriate from then on.

Thanks,

Roy

-

The stock is the original "Bubba'd" When I had to buy another rifle (my first attempt at rebarreling a while back didn't go real well) it killed the budget for one of richard's seconds. still need the recoil pad and to install the swivel studs but I kind of like the ultra-lite design need to get the pad on hit it a few more times with tung oil. the only thing other than the stock now is a post I am going to use I saw a while back about 1/4 lag bolt groung and drilled for a magazine button and an ideal I came up with looking at a 1/4 carriage bolt and the safety the 1/4 carriage bolt slides in the safety opening I already cut the fire cut out and the safe notch I am planning on welding a squareded cut and bent suspended ceiling hanger( comes out flat and wide after the threads makes a good thumb area) to it and notching the shroud to keep it in (and will heat treat with mapp and atf which I read somewhere else here.

Thanks Guys,

Roy

-

Thanks usmc I like the imersion pipe idea but I only have arc.

-

Thanks the welding has been alot of trial and error you should have seen some of my practice attempts

-

Its not hard to do I used a sharpie to scribe the lines used a triangle file to cut them a little and cut a piece of pallet to the inside dimensions from a jig plan I got off the internet locked it in the vise and started tapping it over on the block.

when both sides are done tap the top rails down on the block tap the block out and you have a reciever, I arc weld the lower rails in but you can rivet screw or spot weld them

I have a lot of info on building these if you want me to email it to you.

-

I cant stone some of the areas on a m48 that is really rough and the wheel isn't doing much any ideas on abrasives, compounds or wheels. the dremmel stones and sanding bits are only making it worse. I am using a hf 6" buffing wheel and white rouge

Thanks

-

This was a nice break from some of my mis haps on my first mauser.

It was easier than I expected it is a built from tapco flat and Romanian ak kit from tapco (comes with a g2 trigger 3 of the compliance parts the others are the flat grip stock and fore end also have the US base plate and Follower a little over kill for compliance) I scribed the flat from templates on the net and bent it with a vise and steel bars

-

After I turned one of these into a "Trophy" I picked up a beat up one to start over

all the ideas are stolen from you guys, Thanks its starting to look like it will be a rifle

I broke down and bought a barrel vise and it just spun off

"trophy" at bottom

I spaped the bow like one that was posted

I stoned the crest and other stampings off (not Serial)

notice I'm not showing the top, Middle hole on scope base will need to be egged a little

I used a wheeler bolt knob homemade welding jig from vise and welding magnets

cut a tin can so only the stub came through so arc clean up would be minimal there wasnt any splatter the can worked great (70amp, E6011electrodes)

some blue on the top but none on the cut out or safety lug, Homemade heat sink made out of 1/2" carriage bolt and iron and C clamps anywhere I could put them

I'll post more as I move along

Thanks again

-

I was cleaning out my file cabinet looking for a copy of a trigger mod schematic and found these, I had printed them from a board a year or two back. I hope there helpful.

Roy

http://i21.photobucket.com/albums/b290/bub...ueProcedure.jpg

http://i21.photobucket.com/albums/b290/bub...BlueFormula.jpg

-

Thanks for the list

I've already printed it out I'll be able to check out a few even if it is just window shopping.

-

Tinker,

My fiance's family is in monroeville and elizabeth, I'll be out in your neck of the woods for Christmas, When I get this finished I'll have to bring it out on my next trip so I can show it off. Thanks for the offer but I already asked sonic to do it. no one here in philly I know sporterizes so this board and a few others have taught me most of it so far I've sporterized a turk(stock barrel) butchered an m48 and built a romanian ak-47 from a parts kit and a tapco flat (with all the compliance parts) I was at the valley forge gun show today and didn't even look at any sporters, this is more fun. I'll need some escape time from her family out there any good shops that carry milsurps you recomend in Pittsburg?

-

I have a remington take-off gunsmith is quoting me $100.00, machine shop quoted me $25 until I said it was a barrel then they didn't do that type of work

-

Anyone rethred barrels to small ring threads, please let me know. I have been going to shops in philadelphia and rethreading costs more than a new small ring barrel would and I can't find one in 300wm please help

Thanks,

Roy

-

I spoke to a guy at the range who sounded like he knew what he was talking about , rockwell hardness and all that, Who told me that fast heating is how it warps?

-

Thanks,

Point taken

Roy

-

I may have a solution for a heat treating oven. My girlfriend moved in with a ceramics kiln. I wired up a line for it and started asking some question on how it worked. It slowly heat up to max of 2000 degrees over a period of about 10 hours

you can limit the temperature with things called cones when it hits the temperature the cone is good for the cone melts turning it off. I'm thinking I could bring it up to 1800- 2000 (until its cherry)quench a receiver and then bring it back up to about 900 (I'm not sure about this one but until its purple)and let it cool any one have any opinions on if this will work. since it heats slowly it shouldn't warp anything. any opinions would be appreciated

Thanks,

Roy

-

I am not sure if there saying having 54 guns is illegal but they sure as hell are alluding to it as a crime.I think the kid should go away for a long time but what does A have to do with B

-

has anyone ever used brownells gun cote, I want to try it in the matte black or the brushed stainless I dont know if it will look "spray painted" or just bad.

Thanks

-

Nice Rifle, I hope mine comes out half as good

-

The first one I did I just cut down the stock, filed the steps down , drilled and tapped it, welded a new bolt on and glass bedded it. in 8x57 its as accurate as the commercial 70 and 77 I've had, if I would have wanted to stop there it would have been a great value for the money, but once that came out good I got hot to try some of the other stuff I read about on a post real similiar to this one but I cant find it anymore .If I factor in the tools I have so far (which arent anywhere near what I need) I can't say its Cheaper, but even after some mistakes getting into my first rebarrel job(no patience , not the best homemade barrel and action vises) I really enjoy it. I just made an action into a paper weight but I started on a new one this weekend and from experience I got of off this site I'm in a better position when I get to removing the barrel again, (bolt and bottom metal are done from last one). There is a real satisfaction in looking at a even pieces when there finished and knowing I did it my self.

and now I will never forget An action vise, barrel vise, patience are all thats necessary to remove a mauser barrel.(I don't like $105 lessons)

-

Yeah it is pretty bad, I don't want to have to worry about it,I guess its my first "Trophy" I like Doble Troubles way of looking at it. And I would'nt want my fiance to have a bad experience because of me not being responsible, it took six months when we first met to get her to go to the range and fire a gun (liberal parents). Thanks for all the advice I'm getting another one this weekend (the convincing won't be hard this kept me out of her hair for a few weekends) so I'll probably Be asking for more advice, NOW THIS IS A MISSION.

By the way she actually loves my old Ruger mk1, her NRA membership is next.

-

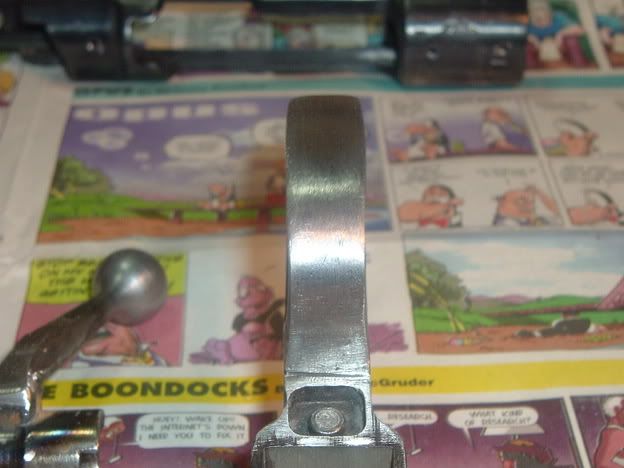

Here are the pics, what do you think?

http://i21.photobucket.com/albums/b290/bub...er/threads3.jpg

ttp://i21.photobucket.com/albums/b290/bubbamauser/threads2.jpg

http://i21.photobucket.com/albums/b290/bub...er/threads1.jpg

Removing Mauser Charger Guide

in Machine Work

Posted

Now you tell me It took about 8 hours to get that ****'er down, I thought because of the hardening it had to be done that way