-

Posts

2,042 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Horsefly

-

Thanks Ken. That’s what I’ll do. Never done it before so will be cool learning sumpin new.

-

I like, totally agree with all that was said !

-

-

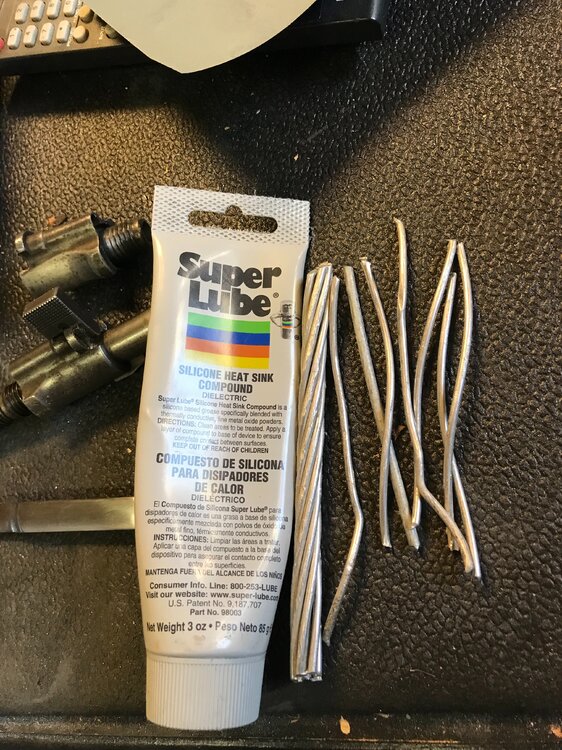

This is my Jerry-rigged heat sink for the 95 bolt weld. Filled bolt body with paste, then put piece of aluminum cable in and finished filling space with strands of cable. Tapped last couple strands in with mallet.

-

-

The hole isn’t threaded, so I’ll tap,plug, and file down. Thanks fellers.

-

Cut the end off the alignment bar so I could drill front scope mount hole with barrel installed. Worked perfect. Got a caliper measurement on how deep the front screw stuck out of mount and set my drill press indicator on that measurement with just a hair more depth. Then finished hole with bottom drill. Taped then cleaned hole with bottom tap. Came out great.

-

I may try Parkering it. Think I’ll tap it and file down plug like you said. I’m not real concerned if it takes blue different than barrel. Hunting gun !

-

I need ideas on filling it.

-

The small ring bolt sleeves (shrouds) are out of stock at Brownells and Midway. May try removing the safety hole on a spare sleeve I have.

-

Once they found the screw-ball that killed his girlfriend dead in the Florida swamp,story is finished. I feel left hanging wondering how the crazy SOB killed himself and if his parents were involved.

-

-

That would be dang good History Channel show. Beat the heck outta Oak Island. Josh Gates would be a shoe-in host.

-

An older friend told me you go from dirty old man to cute and your considered harmless. I try to convince myself women wear the heat-shrink britches just for me. I haven’t made it to cute yet, so must keep looks and thoughts to myself.

-

I started welding with the mig but switched to 3/32” 7018 rod. I have trouble on tiny work getting arc started then seeing around the nozzle. Set the bolt against a scrap piece of 1/2” plate, strike the arc and work it to the bolt. 3/32 on 60 amps works good for me. I would make one weld. Walk away and drink a Coke while it cooled. After 2Cokes switched to a beer. Took 2 hrs. but gott’er done. With bolt body packed tight with heat stop paste and aluminum cable strands, heat stayed right at weld. I held it in my hand after ever weld and was barely warm around bolt root. Bolt handle was different story. The pasted is amazing stuff.

-

Turned out great but man I don’t know if it’s worth all the worry and prep work. Now to polish it out.

-

Brownell’s ad saying their shroud fits Swede 95 and 96 concerns me. Why 93 isn’t listed ? Is Swede before 95 a typo ? Reckon I’ll dig out one of my Swedes and see if it’ll fit on a 95 I’m putting together. Thanks Ken98K for telling me Brownells use to have non-safety shrouds. They still list them.

-

Same as a judge sentencing someone in a trial, then have the trial to see all the evidence. I feel like all the super smart genius leaders are dumber than Bubbas like me.

-

Are they interchangeable ? Brownells old catalog list commercial style shrouds as Swede 95 and 96.

-

No way I thought it was right thing to do. Just didn’t have the balls to say no to family. Not one a lib demonrat but let the bastardo’s scare them.

-

Great info Dr. I wouldn’t had a clue what I needed. Thanks.

-

I got the 3rd booster shot yesterday against my will, but it was family that I caved too. I’m 68 and still have my parents that are scared crazy about cornhola virus,and wife lost her brother and cousin her family raised,so putting everyone at ease is worth the stick. If anyone including family said I had no choice I would never have done it.

-

If any of you cats need something just let me know. No stock.