-

Posts

936 -

Joined

-

Last visited

About Sailormilan2

- Birthday 04/25/1950

Contact Methods

-

Website URL

http://

-

ICQ

0

-

Yahoo

Sailormilan2

Profile Information

-

Location

California

-

Interests

Rifle building, shooting, computors, airplanes

Sailormilan2's Achievements

0

Reputation

-

Is this a stock Polytech, or has it been modified with a new bolt? Lots of people change the bolt, since the Chinese made them to slightly longer NATO headspace specs. Chinese bolt will be unmarked on top, USGI bolt will have the manufacturers code and numbers on top. Things to watch out for on a Polytech. The flat washer type spring in the rear site elevation knob may not be strong enough, so the sight knob may not hold zero. Easy fix. Replace with USGI M-14(marked to 10 meters) or Garand(marked to 12 yards). Trigger may be soft. Easy fix. Replace with USGI M14 or Garand. Might as well replace the hammer spring and trigger pin while you have it apart. Recoil spring may be a bit short. Replace with USGI or Orion 7 spring. I think the Chinese had issues with their springs. If you replace the stock with a USGI, or aftermarket, you will have to glue in a spacer(popsicle stick piece works well), or a blob of epoxy inside the stock to prevent the shorter Chinese connector lock from walking out. Note, you may not have any of these issues. But, I have 3, and helped a buddy get one, and I had to do the trigger and sight knobs on his and one of mine. So, I did all of them. Polys are good, well made, and you did not get hurt at that price. The barrels are chrome lined, and are good. Op rods are forged one piece. The threads are metric. So, a USGI castle nut may not work on a Poly barrel. Polytechs work just fine with USGI magazines. There have been some reports that Check Mate magazines has difficulty locking into place(too tight). I have one CM mag, and it does have that issue with my Polytechs. Bassetts are good mounts, but the angled mount like what you have is a bit harder to get the ring height correct one. I have 5, and they all are the picatinney rail type. If you go high mount, you will need a cheek piece. I like the TNVC, because they have a pocket for the mont tool, and a couple of Allen wrenches to work on the scope.

-

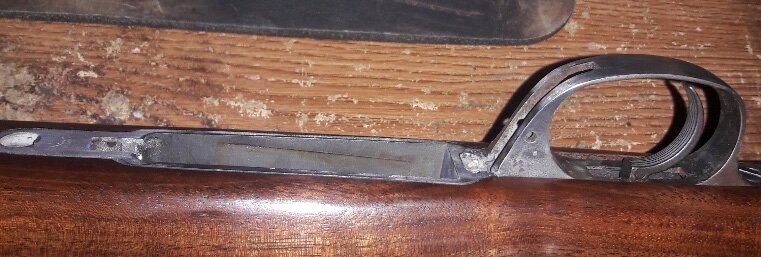

It's been a while since I posted, but I thought I would post pics of my latest idea. Sporterizing Intermediate Mausers is not hard, though it can be problematic due to lack of aftermarket parts. MOST standard Mauser parts will fit and work. But, there aren't any hinged trigger guards in 8mm length out there that will work. Those for the Model 95/96 are usually made for 7mm, and while the screw spacing is correct, the magazine box is not the right length. The Intermediate Yugos are nice to work on, since most are in good condition, having never been abused in a war. They are a perfect length for 243W/308W, 257 Roberts, and a 25-06 will also fit. So, after giving it some thought, taking measurements, and looking at several TGs, I found a donor commercial TG on eBay that someone had drilled a series of holes in it to lighten it. Perfect for my intentions, since that part will be discarded anyway. I took it and an Intermediate Mauser(24/47) trigger guard and cut off the TG bows as close to the rear wall of the box as possible. Then had a neighbor with a wired feed MIG weld the commercial TG bow to the Military TG box. I would have preferred to TIG, but I didn't know anyone who had a TIG welder. I also had him fill in the locking screw hole behind the front TG screw. I took a Parker Hale/Santa Barbara hinged floor plate and used it as a pattern to open up the TG for the hinge tongue. Note: There is a difference between an Interarms MkX/Zastava 70 and a PH/SB tongue. After that, I drilled the hinge pin hole. Once all that was done, it was fairly simple matter to grind/file the floor plate to fit the new box, and clean up the welds. Filing and grinding is done at the rear only. The finished TG was then parkerized to match the rest of the rifle. It turned out better than I expected. it was not as hard as I expected. The "hardest" part was getting the two halves lined up properly. It's very close, but not perfect. It 's now on my Yugo based 243Win with it's PH barrel.

-

-

Numrich has some Chrome lined 18" and 22" barrels made for LRB Arms at a very good price. So, I installed one. Problem withe Chinese made Polytechs and Norincos(Same gun, different name) is that for some reason, the locking shoulders on the receivers have been moved slightly forward from USGI spec. Makes fitting and head spacing a bolt a little more difficult. Especially with the chrome lined barrels. Due to their chrome lining, the chamber is fully cut. So, after installation, one must find a bolt that fits, or lap the receiver and bolt lugs.

-

I'm using Allegheny Arsenal Manganese Park. It's much simpler to use than the Brownells. But it costs more.

-

I've got a couple of Chinese made Polytech M14S rifles that I've used as training aids. I've learned a lot from tinkering with, and modifying, them. But their dark grey color always bothered me. Especially when next to the black color of American parts. So, COVID-19 boredom struck me hard the other day and I decided to "fix" them. I reparked all the Chinese made parts to black. Then put them into cleaned up and refinished USGI stocks. Here they are. The wood on the walnut stock is actually better than what shows up in the photo.

-

Making a hinged trig guard for an Intermediate Yugo Mauser. Updated.

Sailormilan2 replied to Sailormilan2's topic in Mausers

Well, here it is. It's parkerized now. Good color. Unfortunately, the weld didn't take the park well. So, I used Brownells Oxphoblue on it, and that did the trick. -

I applied CitriStriper twice. Scrubbed with a soft nylon bristle brush, and rinsed off with the hottest water my water heater could do.

-

Here it is. 10 coats of hand rubbed pure Tung oil. Then sanded with 400 grit paper. Finally, one coat of hand rubbed Tung oil.

-

Making a hinged trig guard for an Intermediate Yugo Mauser. Updated.

Sailormilan2 replied to Sailormilan2's topic in Mausers

-

I've been tossing around the idea of making a hinged TG for my Yugo Mauser in .243 Win. I got the idea when I realized that the distance from the rear magazine wall to the rear guard screw was the same, whether it was an Intermediate Yugo or a standard 98. The difference in length is all in the front end, basically from about the mid point of the magazine to the front screw. So, I got the idea of finding a donor hinged TG, and doing some cutting and welding. Well, I've had the donor for months now, and finally worked up the courage to do it. Realizing that I don't do this often, and I'm not trained, some of my ideas might not be the most efficient. 1st I hacked off the trigger guard off the donor at the rear mag wall. I ruined a previous Yugo TG, by cutting it in the wrong place, so I was very cautious and conservative today. I cut the military TG right in front of the trigger guard itself. I used and old Yugo stock as a fitting jig, and when placed in there, I had over lap. I ended up cutting the honor TG with the latch, right at the latch. On the military unit, I had to trim back all the way to the mag catch/spring tunnel at the back of the rear wall. I actually had to remove some of the tunnel for everything to fit. Once everything fit, I beveled the edged for a good weld. I would have preferred a TIG welder, but I didn't know anyone who had one. So, my neighbor and his MIG welder got drafted. Unfortunately, there wasn't any real support for the military unit, so it got slightly out of position during welding. Resulting in a slight downward tilt at the weld. But, that won't affect anything, and when in the stock, it's not noticeable. We also filled the front locking screw hole. Which now needs to be cleaned out. There's a reamer for that, and I have one. So far, I've ground down the welds on the sides, so they match the stock contours. Ground down the front screw hole fill, and still have a little to do. I used a 1/4" end mill to open up the hole for the hinge on the floor plate to fit into. Opened with 1/4", then cleaned up a bit with a 5/16". Then filed the end of the cut out square and with an angle inside. Hinge pin hole was drilled a while ago. Currently I'm filling down the latch end of the floor plated once I get it to latch, I will finish profiling the sides of the floorplate at the TG. For some reason, Mausers have a 1/2" square cut just in front of the front mag wall. That leaves very thin metal where the hinge pins will be going. So, my thoughts on that are once everything is done, short of refinishing, I'm going to bead blast all the parkerizing off. The the floorplagte hinge tongue with Brownells release agent, put the floor plate in place with the hinge pin, then pack DevCon Steel bed into the space to give extra support. Rifle will be finished in parkerizing, and I don't believe that the parking solution will affect the DevCon.

-

Just picked up a figured birch stock for one of my M14 rifles. I don't really need it, but it's got the potential to be really nice if finished right. I'm not a fan of really pale stocks, so I have to decide if I should dye it(birch doesn't stain well with oil based stains), or leave it be. Anyway, here's before cleaning and after cleaning pics. Nothing has been done except to clean it.

-

FWIW, Shaw is having a Labor Day sale from now through Labor Day. 15% off.

-

Someone, and I think that it is/was Zastava, made a true left handed 98 style action. At one time they supposedly made some in Stainless steel.