AckleyFan

Members-

Posts

27 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

AckleyFan's Achievements

0

Reputation

-

AckleyFan started following Chamfer barrel , Invision is paid , 8mmx338WinMag - anyone have any experience with this chambering and 3 others

-

I've been OOA for several months, caring for my mother who turned 90 in November. Can someone PM me the email for whoever is taking donations this year (PayPal)? I'm still working and got a bonus this year, happy to kick in.

-

OK - the MAc allows me to resize the images under <Tools> <Adjust Size> they we set at 42 inches, I sized them down to 2 inches and did a copy-paste into the body of this post, looks like they are converted to a .png by the site app. I like embedded images vs. attached, makes viewing so much easier when the platform allows it.

-

A quick update on this rifle - It has a Brown Precision stock - the Kevlar Pound'r. I was stunned to find this stock on it, someone spent a bunch of $ on this thing, that stock is something special - super lite, strong and I absolutely love it. It has a 20 inch Douglas barrel in a lightwieght profile with a radial brake on it - recoil is very mild. It shoots the 200 gr Accubonds at about 2800fps. The previous owner killed a lot of elk and oryx with this combo and noted that his furthest shot was 525yds on an elk - probably getting to the end of its effective range with that Accubond bullet. I'm going to shoot the cup and core bullets as a bonded/premium bullet is not necessary in my opinion based on the velocity numbers for the 200 grain projectile - cost and availabilty are also huge factors. I bought a bunch of Speer Hot-Cor 200 grain bullets, they should work just fine, and the price is outstanding. I measured the bottom metal/mag box - this rifle started life as a 375 H&H Magnum - exactly what I wanted! I purchased a set of 375 H&H bottom metal a few years back to for use on a 280AI build, it's got lots of room for those long pointy bullets. My biggest dilema now is deciding what to do with it - leave it as is or rebuild it back into a 375 H&H for an Alaska/Africa rifle. I'll try to shoot out the current barrel and then decide.

-

Hi All - I've purchased an Interarms Whitworth that is chambered in 8mmx338WM - has anyone here ever had one? Any history on who developed this round and why? I haven't laid eyes on this thing yet as I purchased it online and it's waiting for me to get home and retrieve it from the LGS. It came with brass, bullets and a set of dies. I'm going to take measurements on the bottom metal and try to figure out what it started life as - I'm hoping it was a .375H&H Looks like it has a B&C stock that has been painted to better match the desert environment that the previous owner used it in. Can't wait to work up loads for it using the Speer 170gr Hot-Cor bullets, should do well on black bear and elk at reasonable ranges. Impatiently awaiting for the manufacturers to make a run of the heavier bullets. -Rob

-

Been AWOL for a while... are you still in need of the forging blocks and welding jig? If my brothers didn't run off with them they're in my workshop. I'll lay eyes on them before committing, but happy to send them to you for the cost of shipping when I locate them. -Rob

-

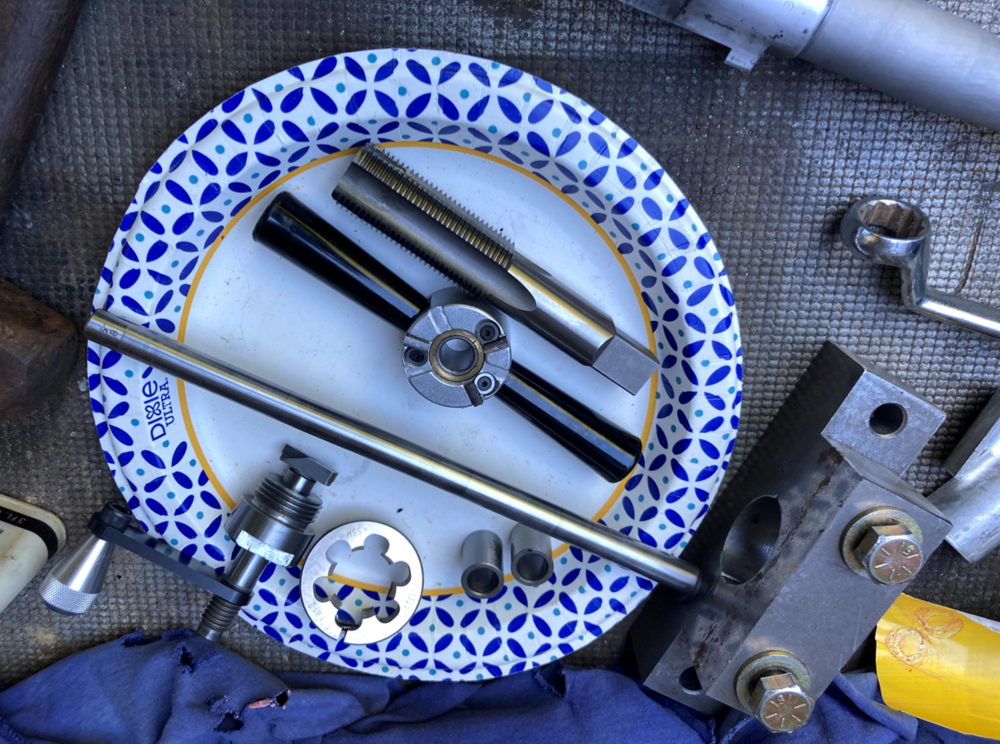

Decided to put the new McGowen barrel on the VZ-24 action today, I staged some photos for ya'll. It's chambered in 280 Ackley Improved (my favorite) #2 McGowen contour @ 26" . My procedure is: face off the receiver with a cutter from Dave Manson, tap and clean up the receiver threads with the Brownell's tap (like a bottom tap), face off the C-Ring with another cutter from Dave Manson, set the C-Ring to receiver face distance so that I have about .003' crush on the barrel mating surfaces - I specify the barrel tenon length so that I have some room for adjustment. The barrel threads needed to be cut down a bit so I set up the die to take a few thousands cut and started spinning it with the screwdriver in the slot as a driver, I can hold it in my hands if I take a firm grip. I cut up to the relief cut which gets about 3/4th of the threads then turn the die around and finish the few remaining threads. Perfect fit. Clean everything. Add lube to the threads and tighten to about 60 lb-ft. Check fit and put tools away. Mix a cold beverage and setup for chamber reaming tomorrow. I had the chamber cut about .040' short so I get the full benefit of the custom reamer leade geometry that Dave Manson and Nathan Foster developed when I finish reaming. Their objective was to develope a reamer/chamber that more gently guides the newer style (longer) bullets that we're using nowadays into the lands. Seems to work well, this is my 2nd build with this reamer and the first one is a tack driver! I have high hopes for this one. No idea which stock I'll use yet - I'd like a carbon fiber job but I'm not made of money... anyone have an idea for a good lightweight stock?

-

For the price of one Cerakote job I purchased all the tidbits needed to spray it myself - Amazon has everything including the Cerakote. This rig has paid for itself several times over, is very easy to use and the results are as good as any "professional" job if you take your time and inspect your work. You only need a thimble full of Cerakote to coat a barreled action, bases, bolt and other small parts as desired. It takes a bit of math to calculate the proportions needed, but those plastic syringes make it easy to do in small quantities. Do not mix the quantity that the manufacturer recommends or you'll waste most of the product. I spray outside on my patio with a piece of cardboard as a wind-break, pre-fit the barreled action in the oven with the hangers created and ready to go. Do not pre-heat your oven, voice of experience talking...

-

Yesterday Sarco had bare 1909 Argentine Mauser actions for sale. I've been thinking about them the past few weeks so I put in an order for 5 of them. I went to Sarco's site today and see that they no longer have any available - I may have purchased the last of them - sorry folks. I was excited to tell you all about them Hope some of you got some! https://www.sarcoinc.com/argentine-mauser-model-1909-receiver/

-

I test fit an EGW base and it was perfect, no shims needed. Drilled & tapped with a barrel I use for mock ups to ensure proper alignment, pits filled, scuffed, it's ready for a shot of Cerakote. I used Sniper Grey for my .308 Winchester project and it looks really nice - reminds me of a parkarized Garand. I'll probably squirt it with Graphite Black though. As you can see, I like the holes drilled well forward of the bolt lug. I've seen several actions with holes drilled smack through the middle of the lug... I suspect using those actioins would be unwise.

-

@Dr. Hess - I has assumed as much but one can never be too sure, so I figured I'd best ask the folks that are more experienced. One of these days I'm going to takes pics and post the results of my various Mauser builds - my version of a "Frankenrifle" is my personal favorite at the moment. Thanks for the responses, I'm moving this build forward as soon as the barrel arrives. Now I have to order the custom reamer from Dave Manson - it seems I never order anything "off the shelf".

-

I'm building a 280AI on this one, need to find another one for a 6.5x280AI project. My wife bought me a 6.5mm barrel from McGowen for Christmas.

-

I have a Brazil contract VZ24 receiver that has been scrubbed/ground, the serial number is still there thankfully. My concern is the case hardening has now been removed from the outside, but naturally is still intact on the inside. When drilling and tapping I noticed the bit run through the outside like a hot knife through butter then make contact with the CH on the inside and slow me down as one would expect. Any issues/concerns with using the receiver as-is or should in be sent off to someplace like Blanchards to be re-hardened? Natually I'm going to build an Ackley with it as these feed rails were almost made for the conversion!

-

If you go to Dave Manson's website https://mansonreamers.com/catalog/ you can download his catalog in a .pdf format and open it in Adobe Acrobat or in a web browser - on page 15 is his Muzzle Crown Refacing Tool Kit, I have one - works great. I have two pilots - .25 and .30 cal with the 0 degree cutter, 11 degree cutter and 45 degree chamfer cutter. This combination makes for a nicely protected 11 degree crown and a perfectly executed chamfer. No gunsmith or lathe needed. There's probably a video or two up on Youtube for reference. Happy to loan this rig to you, but I need it back in about 6-10 weeks. My wife bought me a new barrel for Christmas from McGowen. It's a LR Mauser prefit 6.5mm #2 contour @26" - I'm going to cut it down a bit and re-crown it. Someone must have ordered it then abandoned their project, and I've been wanting to neck down the .280 Ackley Improved case to 6.5mm and go shoot'n. It was a very Merry Christmas at my house! Send me a PM if you're interested in using the tool and I'll mail it to you. I also have a chamfer cutter that I bought of eBay that I use to chamfer the chamber a little deeper/wider - I polish by hand with 600 grit wrapped around a couple of wood coffee stirrers and viola! I'm putting my gunsmith out of business. I thank D'Arcy Echols for this trick.